“Roasting is essentially a process of exposing the green coffee beans to a warming process that is sufficiently fast to drive off the free and bound moisture of the bean and the dried bean residue is heated to more than 400 F. At about this temperature, pyrolysis, or thermal decomposition and chemical change, occurs within the bean.” -Michael Sivetz, Coffee Origin and Use.

Have you ever had coffee that tastes burnt and bitter, or leaves you with a sour stomach and an unpleasant, jittery feeling? We usually attribute these characteristics to a particular style of coffee roast or brand of coffee – though maybe it’s neither. In many cases, it’s the roasting equipment that causes undesirable flavors. You might stumble onto this realization by having a cup of extraordinary coffee, ask what made it so, and discover Air-Roasted Coffee!

With Air-Roasted Coffee, you taste the coffee not the roaster. The air, rather than the surface of the roaster, roasts the beans leaving the coffee with a very clean taste that is intensely aromatic, without the acids and bitter tars produced by conventional roasters. This roasting method was championed by Michael Sivetz, Chemical Engineer and Coffee Industry Consultant. He wrote the first scientific treatise on coffee, Coffee Technology. Disappointed with the state of roaster manufacturing, he developed and manufactured the first practical commercial air roaster: the Sivetz Fluid-Bed Air-Roaster.

Conventional drum roasters date back to the 1800’s and rely on radiant heat from the cylinder walls to transmit energy into the roast chamber. While improvements have been made over the years, the fundamental flaws remain unchanged. In order to achieve sufficient roasting temperature inside the drum the cylinder walls must be heated to excessive temperatures, which causes the beans to scorch and burn. The beans tumble within the cylinder en masse, much like clothes tumbling in a dryer, creating uneven roasting due to inefficient heat transference – even when air is introduced into the drum. Additionally, dust and debris from the beans coat the cylinder in an oily residue that then taint the roasting beans with bitter tasting tars. Updates to the design, including modern roast profiling software, merely mask these issues without solving the problem inherent in the design.

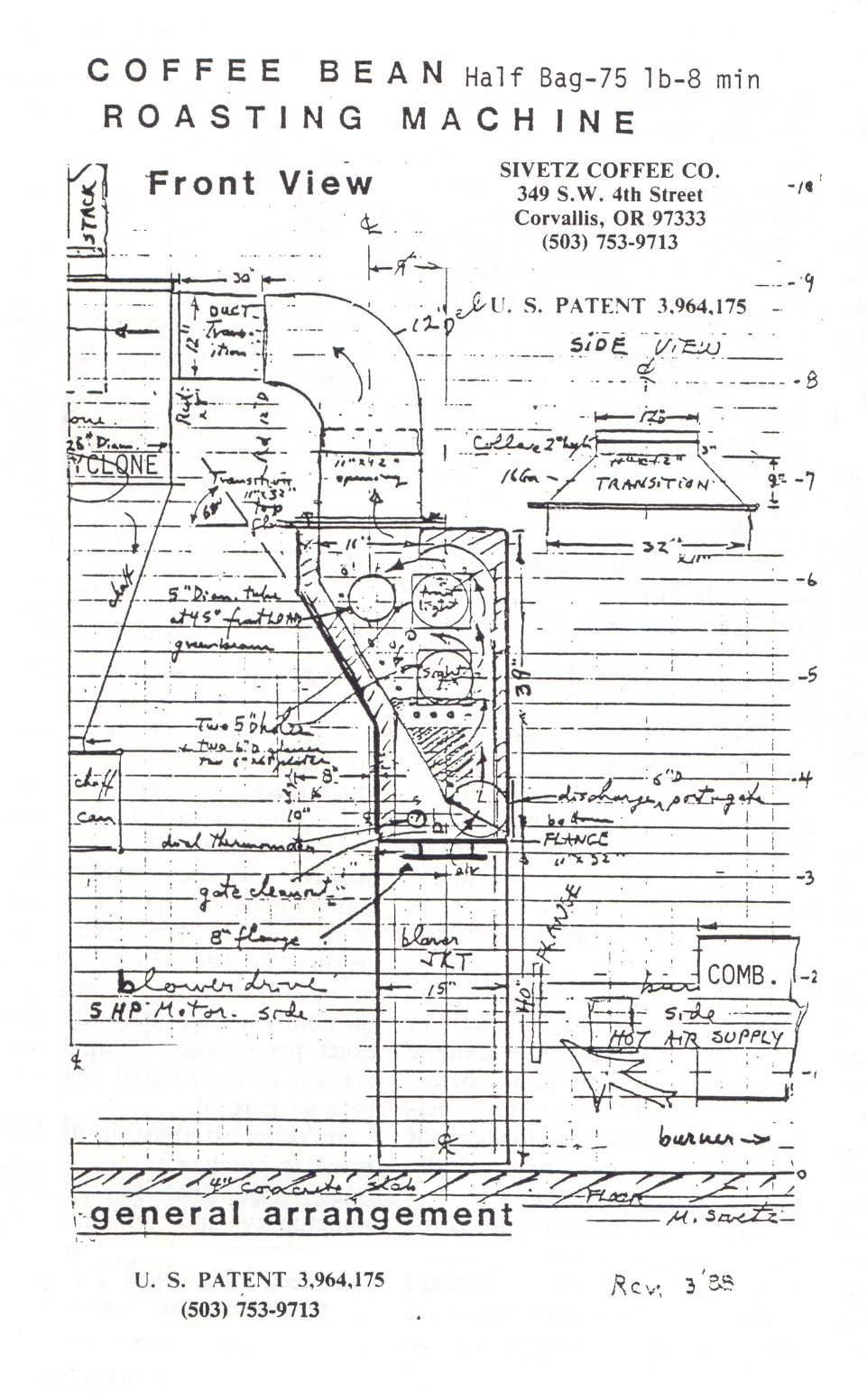

The Sivetz Air-Roaster takes a different approach. Invented in 1976, the Sivetz Air-Roaster eliminates the need for radiant drum heat and instead levitates the beans on a fluidized bed of hot air, keeping them moving and not scorching on hot surfaces. The sole use of hot air greatly increases the rate of heat transference to the beans, optimizing roasting times, creating a cleaner, more aromatic roast free of bitter tasting tars. The moisture in the green beans is driven off quickly, reducing soury tasting acids. Additionally, the high volume of air immediately removes dust and debris from the beans so that the roaster walls – and the coffee – remain clean. The progress of the roast is measured accurately by bean temperature, allowing for consistent and precise roast profiling.

The benefits of Air-Roasting mean you get consistent, cleaner, more aromatic coffee with less acid – all makings of an extraordinary cup.

COMPARING DRUM to Hot Air Fluid Bed Coffee Bean Roasting

By Michael Sivetz

In 1975 Sivetz invented and patented an improved method for roasting coffee beans.

TIME of Roast

Drum roasting has been and still is a poor way to transfer heat to the bean.

For example, a fluid bed roasted commercial batch of green beans can take l5, 20 or more minutes to roast, whereas the same sized batch can be roasted in 6 to 8 minutes in the patented Sivetz roasters. This halving of roast time, alone, not only constitutes doubling productivity, but it produces a brighter, cleaner, improved tasting and more aromatic coffee bean.

The Sivetz process only passes the hot air once through the spouting bean bed.

The significance of this procedure is that any and all loose chaff is immediately swept away from the beans into the cyclone collector. The chaff is unsinged. Whereas, in a drum roaster most of the chaff rides on the tumbling beans and burns and smokes. This smoke, fumigates all other beans, giving them a harsh bitey taste. The smoke also deposits on the surface of all other beans, resulting in darker bean surfaces than interiors, and oil surfaces. This carbonization of the drum roasted chaff creates volatile products similar to those found in cigarette smoke and charcoal preparation from wood. These are classified as carcinogenic chemicals.

The metal drums build up in oily, carbonized lacquers, causing poorer heat transfer rates from the metal drum to the beans (conduction), and the roaster operator needs to increase the temperature of the drum, in order to keep roasting at minimal times. Since most of the heat passes through the steel drum wall, usually the drum deposits need to be removed about once per week, down to the metal surfaces. Such frequent cleaning takes many hours of labor, and is never totally completed. People who own and operate drum roasters, especially when preparing dark roasted beans, need to realize that they are doing work that is not done on the Sivetz maintenance free fluid bed roaster, with only one moving part.

The reasons for this difference, are not only due to higher steel drum temperatures, but also the slower bean and air movement, with metal tipping hot spots on the beans releasing oils, and the smokey chaff tar deposits both on the beans and metal parts.

The fluid bed roaster, on the other hand, because of its lesser inlet air temperatures, and vigorous bean movement keeps the roast chamber wall scoured and clean to the metal surfaces. There is no need to spend time and labor to clean the roast chamber weekly.

The roasted beans from a Sivetz fluid bed roaster have a clean smooth taste, that does not leave an after taste coating in ones mouth, that requires a glass of water.

BEAN TEMPERATURES & Degree of Roast

The biggest benefit offered by the Sivetz fluid bed roaster, is its ability to sense the digital bean temperature accurately with a thermocouple. Hence with this information, the degree of roast is known at all times, as well as allowing easy settings for different degrees of roast and offering accurate reproducibility of roasts.

This is not easily done on a drum roaster, when intermittent probed bean samples and operator eye judgments are used.

In todays market, many large (say 4 bag) drum roasters have bean catching troughs where bean temperatures are measured. However, these methods have not been used on the smaller specialty sized drum roasters. Such bean color samplings, if not verified, can often give inaccurate bean temperatures, hence inaccurate degrees of roast.

Many production people in the specialty trade are not even aware of this bean temperature relationship to degree of roast taste, weight loss, and light reflectance. Systems that measure the reflectance of ground coffee, can only tell what has been produced, and is not a way to directly influence the termination of the roast, while roasting.

One must keep in mind that most large roasting firms all over the world have purchased Neuhaus-Neotec fluid bed roasters based on the Sivetz principles (previously licensed). Many of these machines are doing 4 minute roasts. So one can appreciate that not only have the majors quickly accepted this way to roast, but that in using more productive Sivetz fluid bed methods, there is a rapidly growing portion of the worlds coffees being so roasted and displacing the older less efficient drum roasters.

UNIFORMITY of ROAST COLORS

There have been a few so-called fluid bed roasters built and operated in the past, namely Lurgi 1 Kg unit, Smitherm continuous pressure roaster and Wolverine hot air down blast design on to a vibrating conveyor. Each had some deficiency which limited their commercial use. The basic principle of a fluid bed roaster or drier is that the granular bed is totally uniform in temperature and other properties regardless of where you stick your probe. This is true of the Sivetz fluid bed roaster. The Wolverine method did not give uniform roasts as evidenced by bean colors alone. So it could be used for ground coffee sales but not bean sales. Also none of the listed prior methods measured bean temperature accurately, if at all. A body of beans needs to be uniform in color or chemistry from bean to bean as well as from the surface to the center of the bean.

As already noted, drum roasters deposit smokey tars on the bean surfaces, especially at darker roasts. Beans roasted to the same weight loss are darker on the surface than within from a drum roaster, whereas, the bean surface is lighter than the interior of the bean in a fluid bed roaster. One reason for this is that the Sivetz fluid bed processed beans have no dark tars on their surfaces.